CO and NO₂ Noxious Fume Control Systems in Car Parks

Effective, Economical Control Compliant with AS 1668

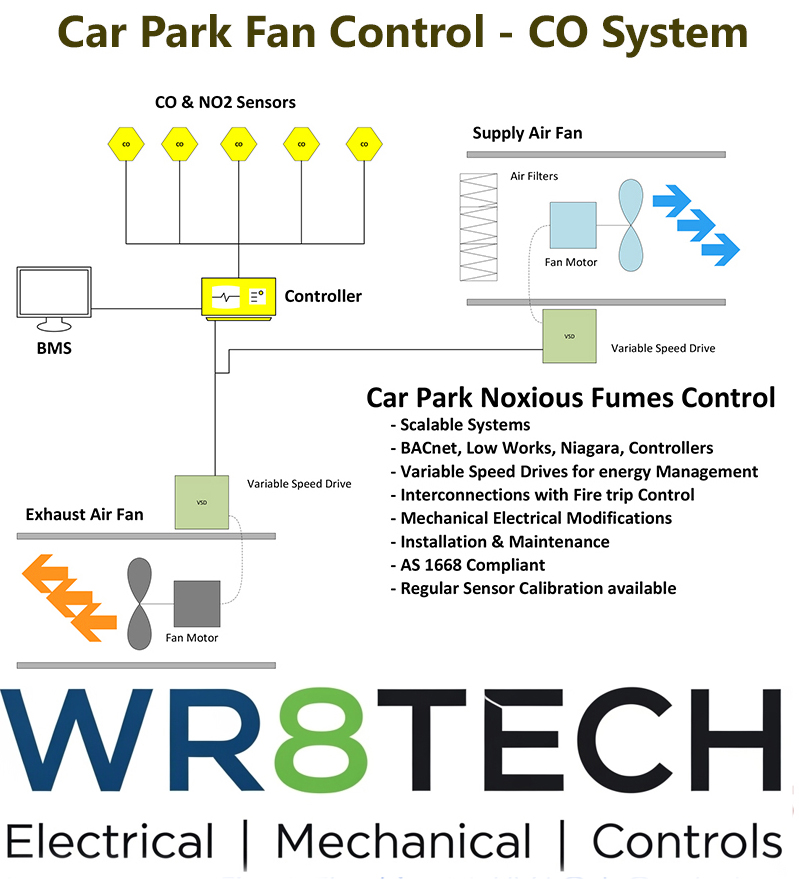

A CO and NO₂ car park ventilation control system provides an effective and energy-efficient method of managing noxious vehicle exhaust fumes, fully compliant with AS 1668.

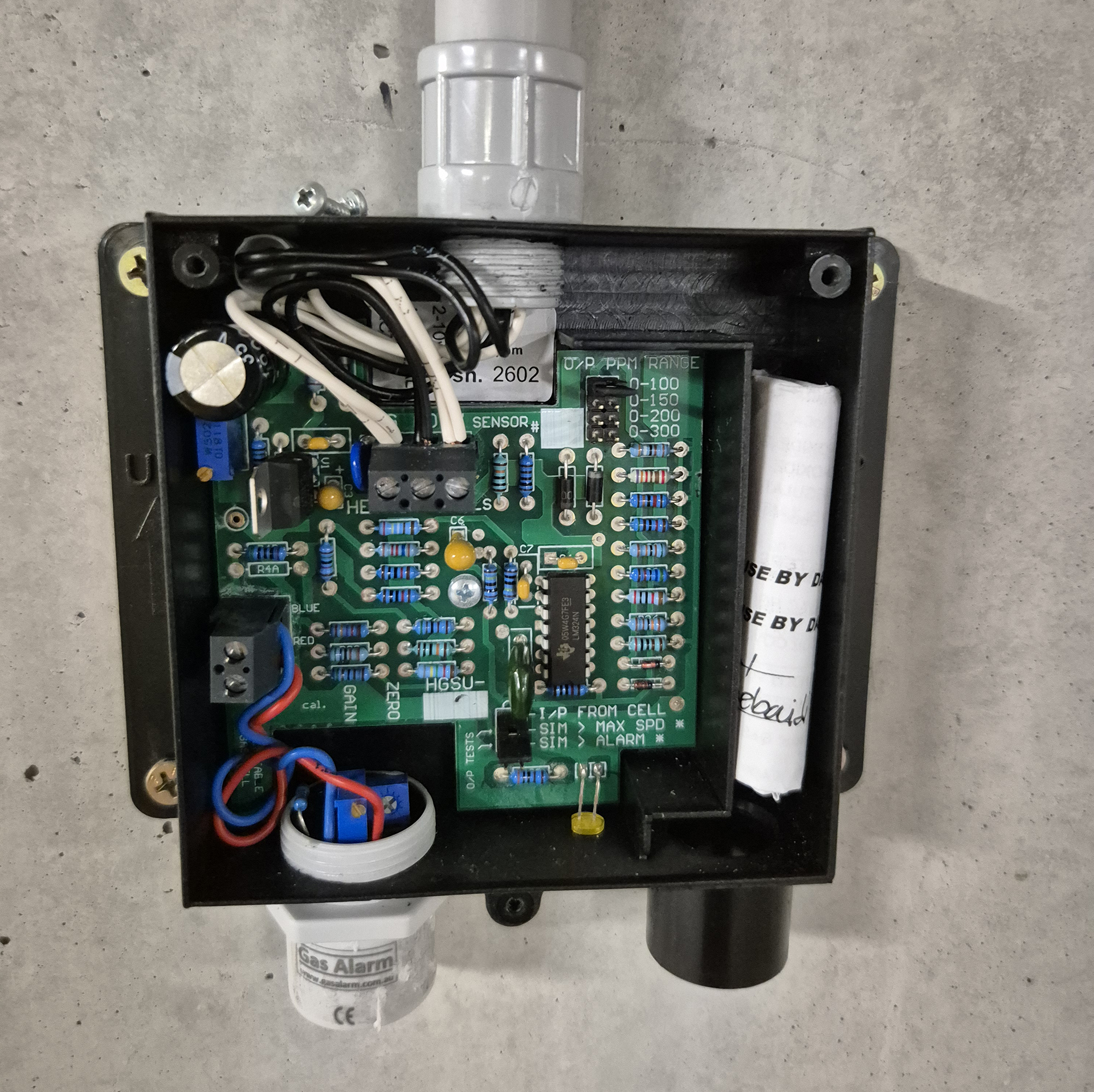

Carbon Monoxide (CO) sensors, used to detect petrol vehicle exhaust fumes, and Nitrogen Dioxide (NO₂) sensors, used for diesel exhaust fumes, are installed throughout the car park in accordance with an engineering formula. This formula considers both the physical behaviour of the gas (such as whether it is lighter or heavier than air) and its toxicity.

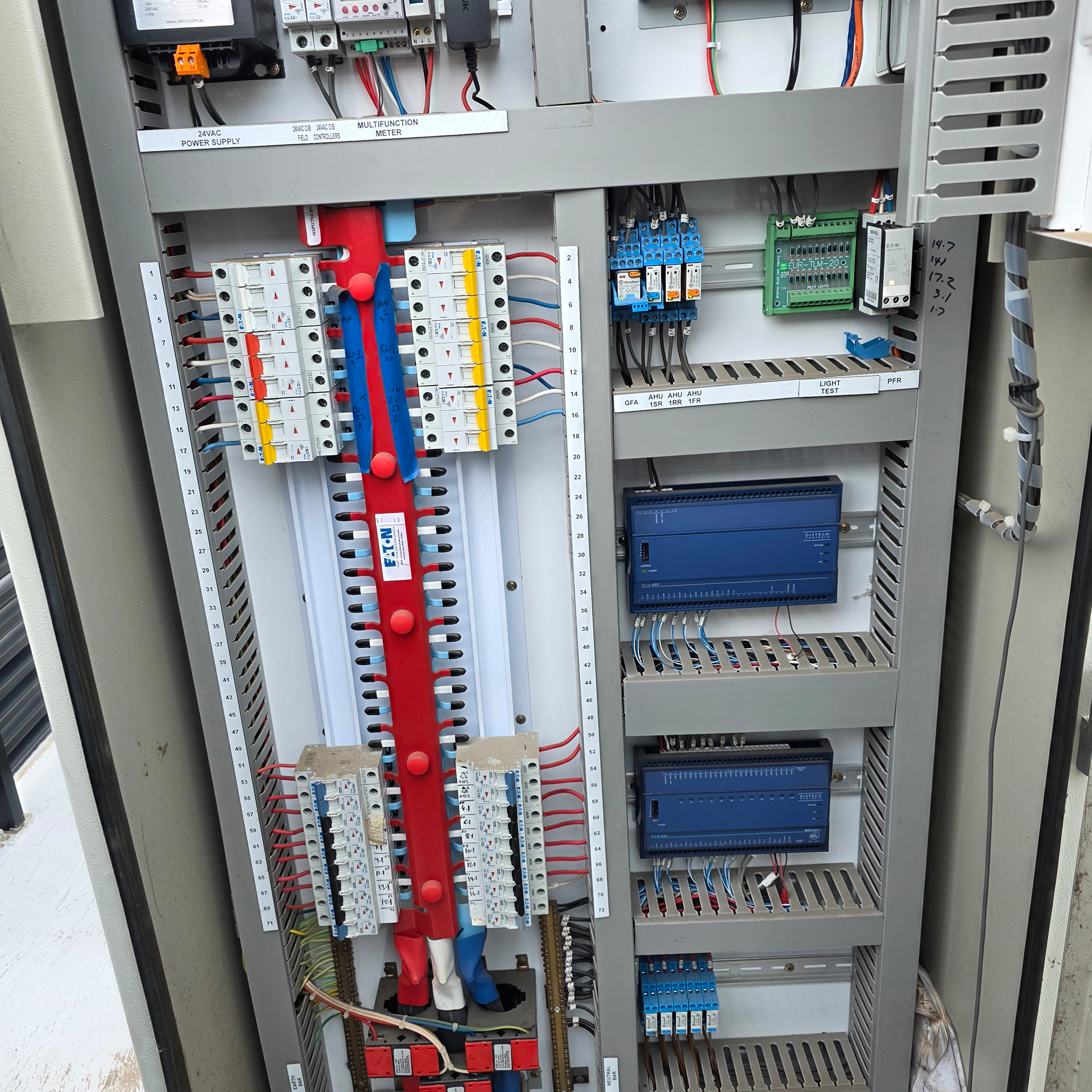

Each sensor is hard-wired back to a central controller, typically using a three-wire configuration. The controller continuously monitors the sensor inputs, which are analogue values expressed as a percentage of the allowable gas concentration.

When gas levels exceed a predefined threshold for a specified duration, the controller automatically signals the car park supply and exhaust fans to operate. The fans then run for a programmed period to dilute and remove contaminated air.

All time delays, set points, and operational thresholds are configured to meet or exceed the minimum requirements of AS 1668.

Fan motors are connected to Variable Speed Drives (VSDs), enabling soft start-ups that significantly reduce energy consumption while minimising mechanical wear and tear on the plant.

For life-safety integration, the supply and exhaust fan controls are interfaced via relay outputs with the base building fire trip system, ensuring coordinated operation during fire events.

Car Park Co System Exhaust Fans

Car Park CO & NO₂ Fume Control Compliance

For Sydney & Melbourne Commercial Buildings

All enclosed and semi-enclosed car parks in Sydney and Melbourne must manage vehicle exhaust fumes in accordance with AS 1668 – The Use of Ventilation and Air Conditioning in Buildings. This standard exists to protect occupants, contractors, and visitors from harmful exposure to vehicle exhaust gases while ensuring systems operate efficiently and economically.

What the System Does

A CO and NO₂ fume control system automatically monitors air quality within a car park and activates ventilation only when required. This ensures the building remains compliant without running fans continuously, reducing unnecessary energy use and equipment wear.

How Compliance Is Achieved

Carbon Monoxide (CO) sensors are installed to detect petrol vehicle exhaust fumes, while Nitrogen Dioxide (NO₂) sensors detect diesel exhaust fumes. These sensors are positioned throughout the car park using an engineering formula that considers how each gas behaves in air and its toxicity level.

Each sensor is connected back to a central controller that continuously monitors gas levels. When concentrations exceed allowable limits for a defined period, the system automatically starts the car park exhaust and supply fans to dilute and remove contaminated air.

All activation thresholds, run times, and delays are set to meet or exceed the minimum requirements of AS 1668, providing a clear compliance pathway for building owners and managers.

Energy Efficiency and Asset Protection

Ventilation fans are controlled via Variable Speed Drives (VSDs), allowing motors to start and run smoothly rather than at full speed. This significantly reduces energy consumption while extending the life of motors, bearings, and mechanical components.

By only operating ventilation when air quality requires it, the system delivers compliance without the high operating costs associated with constant fan operation.

Fire and Life Safety Integration

To meet broader life-safety obligations, the car park ventilation system is interfaced with the building’s fire control system. In the event of a fire, fan operation is controlled via fire trip relays to ensure safe and coordinated system behaviour in accordance with fire engineering and statutory requirements.

Why This Matters for Sydney & Melbourne Assets

Regulators, insurers, and fire authorities increasingly expect documented evidence that car park ventilation systems:

- Comply with AS 1668.2

- Are correctly configured and maintained

- Are integrated with fire systems

- Operate efficiently and reliably

A compliant CO and NO₂ (Diesel Engines) control system protects occupants, reduces risk exposure, and prevents unnecessary energy and maintenance costs.

Risks of Non-Compliance

Fines, Insurance Exposure & WHS Obligations

Failure to maintain a compliant CO and NO₂ car park ventilation system exposes building owners and managers to multiple layers of risk — financial, legal, and operational.

Regulatory and Statutory Risk

AS 1668 is routinely referenced by building certifiers, fire engineers, councils, and state regulators across NSW and Victoria. A non-compliant or poorly configured system may be identified during:

- Fire safety inspections

- Annual Essential Services reviews

- Building audits or change-of-use assessments

Non-compliance can result in:

- Rectification notices and enforced upgrades

- Delays or refusal of Fire Safety Statements or Essential Safety Measures sign-off

- Regulatory fines and penalties under state building legislation

Insurance and Liability Risk

Insurers increasingly require evidence that life-safety and ventilation systems are:

- Installed and configured in accordance with relevant Australian Standards

- Maintained and tested at prescribed intervals

- Integrated correctly with base building fire systems

If a noxious fume incident occurs and the system is found to be non-compliant, disabled, or incorrectly set:

- Insurance claims may be delayed, reduced, or denied

- Liability may shift directly to the owner or Owners Corporation

- Directors and committee members may face personal exposure under duty-of-care obligations

.

Indirect cost of non-compliance is safety

Work Health & Safety (WHS) Exposure

Under NSW and Victorian WHS legislation, building owners and managers have a primary duty of care to provide a safe environment for workers, contractors, and occupants.

Inadequate control of vehicle exhaust fumes can result in:

- Elevated carbon monoxide or nitrogen dioxide exposure

- Health impacts including headaches, dizziness, nausea, or more serious outcomes

- Breaches of WHS duties if risks are foreseeable and not adequately controlled

WHS incidents involving toxic fume exposure can trigger:

- Regulator investigations

- Improvement or prohibition notices

- Significant fines and potential prosecution

Operational and Reputational Impact

Beyond compliance and safety, non-compliant systems often lead to:

- Excessive energy costs from fans running continuously

- Increased mechanical failures and unplanned maintenance

- Tenant complaints and reputational damage

- Reduced asset value and increased scrutiny during asset sales or refinancing

The Practical Reality

In most cases, non-compliance is not caused by system failure — but by:

- Incorrect sensor placement

- Poorly configured set points or run times

- Disabled or bypassed controls

- Lack of testing, documentation, or performance verification

A compliant, performance-based CO and NO₂ control system reduces risk across regulatory, insurance, and WHS obligations while delivering lower operating costs and long-term asset protection

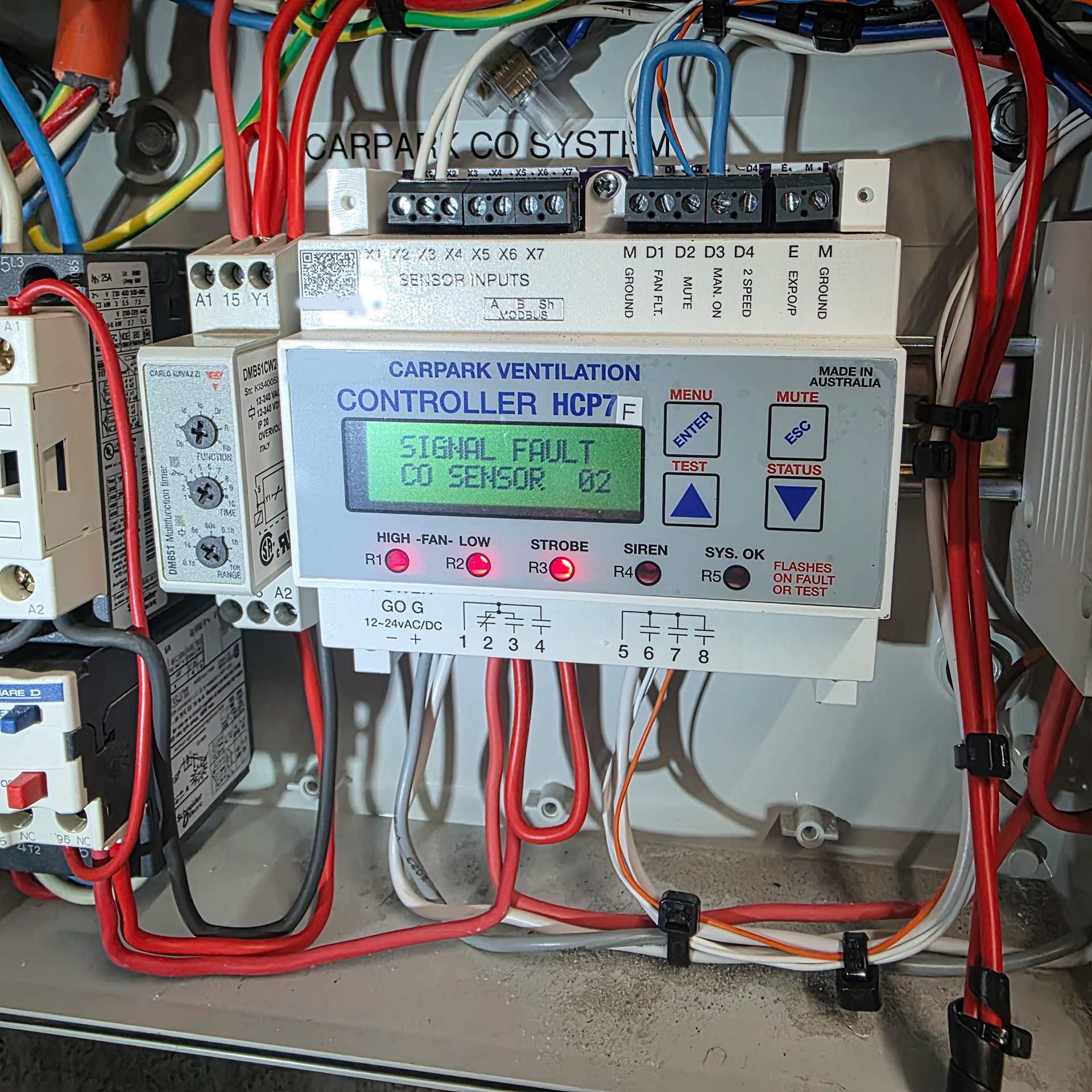

Carbon Monoxide Systems Controller

Carbon Monoxide controllers are specifically purpose-built and progrmmed systems. A BMS controller can do the job, but it needs to be programmed with conditional variables which trigger the fans for equal compliance to AS 1668-2 and indirectly AS 1851.

There are core functions it must have (this list is not exhausted)

- Sensor fault – if a sensor goes into fault the system must run the fans to 100% continuously until the fault is recififed.

- Carbon oxide set points levels

- Fan run on times

- Alarm or sirens

- Car Park Flush once every 24 hours

The Occupational Safety and Health Act, section 21, Ensures any Carbon monoxide-controlled ventilation system is regularly serviced, and records kept, ensuring CO levels do not exceed exposure standards. Carbon monoxide sensor test & calibration is an essential service

AS1851 and AS1668

In Victoria and New South Wales, Courts are referencing AS 1851 as the benchmark for “reasonable maintenance”.

A smoke exhaust, stair pressurisation, or carpark ventilation system was designed under AS 1668, then:

An AFSS cannot be truthfully signed unless:

- All relevant fire safety measures have been:

- Tested at the frequency required by AS 1851

- Tested to the method defined by AS 1851

- Properly documented with pass/fail outcomes

- Any non-compliances are disclosed

- Any critical defects are rectified or managed

In short:

AFSS becomes an evidence-based declaration, not an administrative exercise