What Are “Legacy Systems” in Commercial Buildings?

Legacy systems typically include:

- Older BMS / BMCS platforms

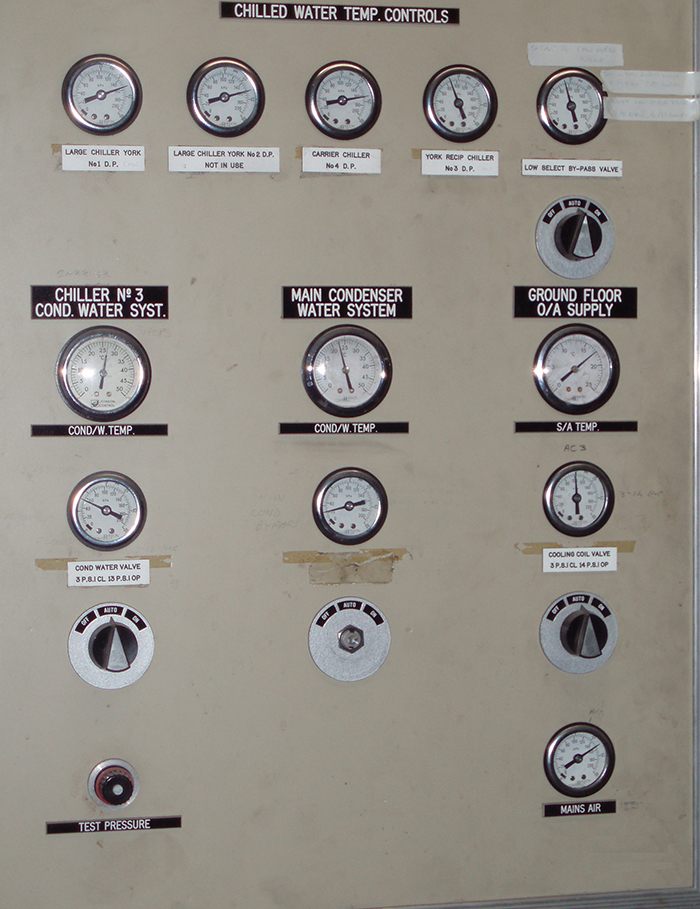

- Stand-alone HVAC controls

- Analogue Control Systems (Transistor, modular, electronic)

- Obsolete PLCs or relay-based logic (low-level interface)

- Ageing electrical switchboards

- Non-networked exhaust and car park ventilation controls

- Fire systems which have not been upgraded (non-addressable)

- Mechanical (HVAC) operating in isolation, zero communications with peripheral yet fundamental equipment

- electrical systems operating in isolation, energy consumption is higher than necessary, schematics are inaccurate and not current

- Pneumatic control systems without any digital interface or low-level interface to other peripheral equipment

- Elevators using relay logic

Integration of Legacy systems can:

- negate or reduce the need for specialist expertise that only a diminishing number of contractors can service.

- support to improve current NCC, WHS, and Australian Standards, compliance and audit risk

- Extend the life on unsupported software and discontinued hardware

- Open buildings into multi-vendor arrangements, removing price tension and commercial leverage

- Improve cost-effective maintenance, create longer lifecycle

- negate or reduce the likelihood of suppliers escalating pricing on obsolete equipment.

Tansducers

Electronic/Digital to Pneumatic Transducers

Electronic-to-pneumatic and pneumatic-to-digital transducers provide a highly effective pathway to modernise control strategies without triggering unnecessary capital expenditure on wholesale plant replacement.

While there is a broad range of conversion devices available, the critical decision drivers are whole-of-life cost, remaining asset life, and risk exposure. This is especially true for control and isolation valves, where full replacement can rapidly escalate into major capital works once associated plumbing modifications, shutdowns, recommissioning, and compliance sign-off are considered.

In many cases, integrating legacy pneumatic controls delivers equivalent functional outcomes at a fraction of the CAPEX, preserving existing mechanical assets while extending their serviceable life. Integration is typically performed at the pneumatic control panel, allowing modern digital control systems to coexist with proven pneumatic infrastructure.

This approach is particularly strategic for large valves, steam systems, and hospital environments, where asset criticality, redundancy requirements, and operational downtime make replacement both costly and high-risk. By retaining serviceable pneumatic plant and integrating at the controls level, building owners can defer capital replacement, smooth long-term expenditure, and maintain compliance without compromising performance or reliability.

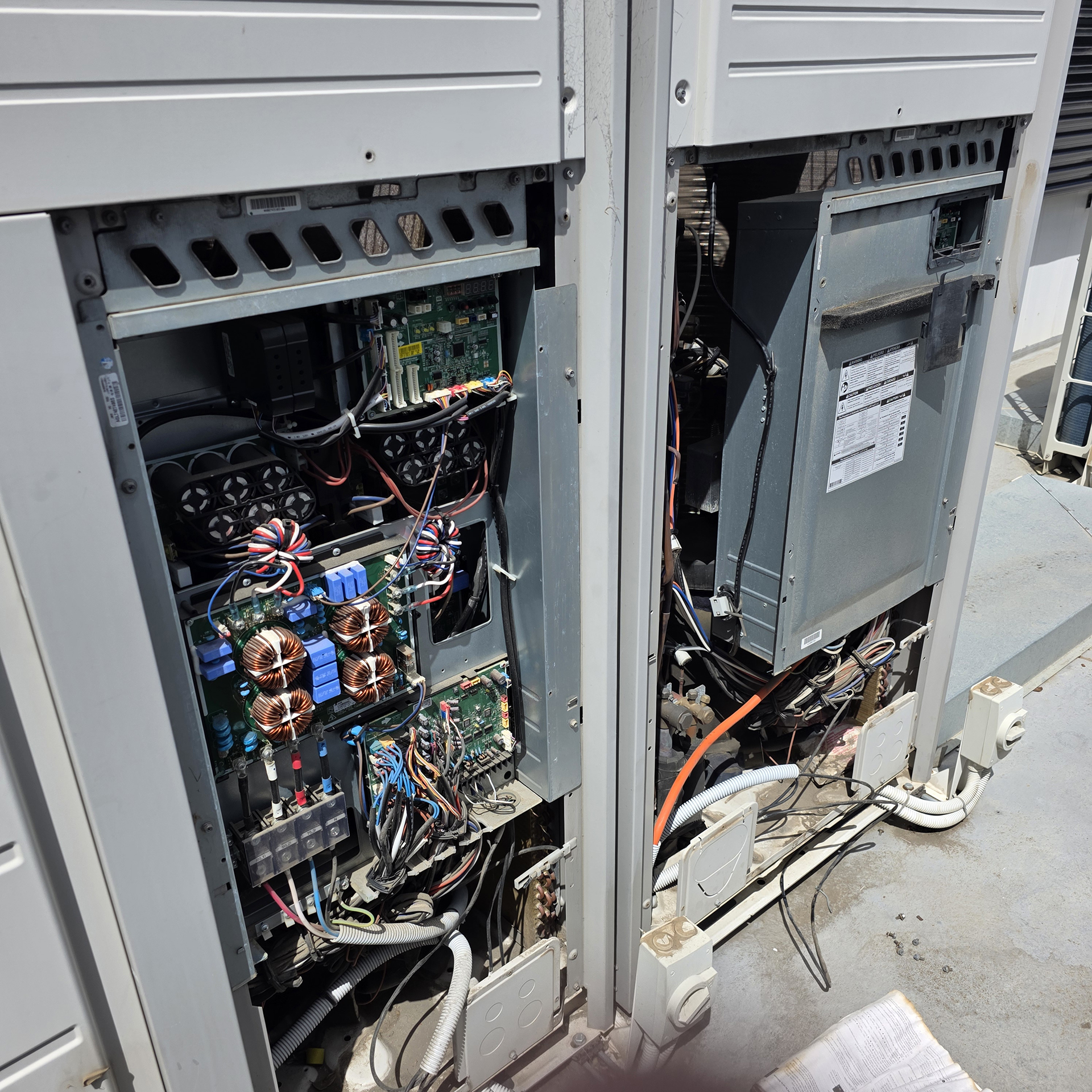

VRV & VRF Systems

In recent years, Variable Refrigerant Flow (VRF) and Variable Refrigerant Volume (VRV) systems have become increasingly prevalent in commercial property installations. Their adoption is driven by proven reliability, high energy efficiency, compact and modular plant design, flexible zoning capability, and scalability across a wide range of building types.

Major manufacturers typically provide built-in integration capability at both high and low levels. High-level communications are commonly available via open protocols such as BACnet and LonWorks, while low-level integration is supported through relays and volt-free contacts—covering the majority of both current and legacy systems.

As a result, integrating an existing VRF or VRV system into a Building Management System (BMS) is a logical and cost-effective step, rather than a replacement exercise. For building owners and tenants, the key benefits are enhanced control, improved operational visibility, and proactive fault monitoring. Early detection of faults enables issues to be addressed before performance degrades, tenant comfort is impacted, or temperature control is lost—protecting both asset performance and occupant experience.

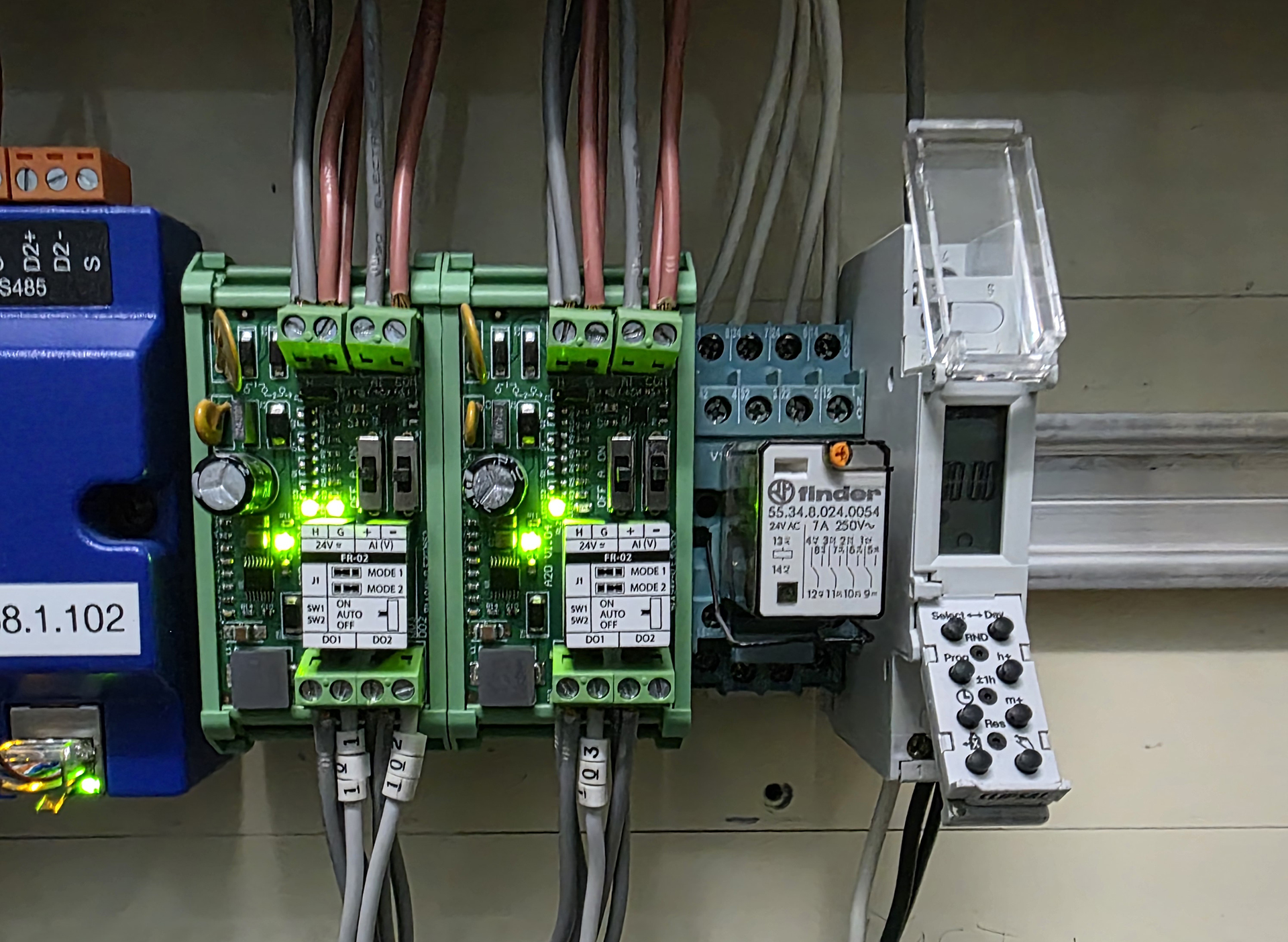

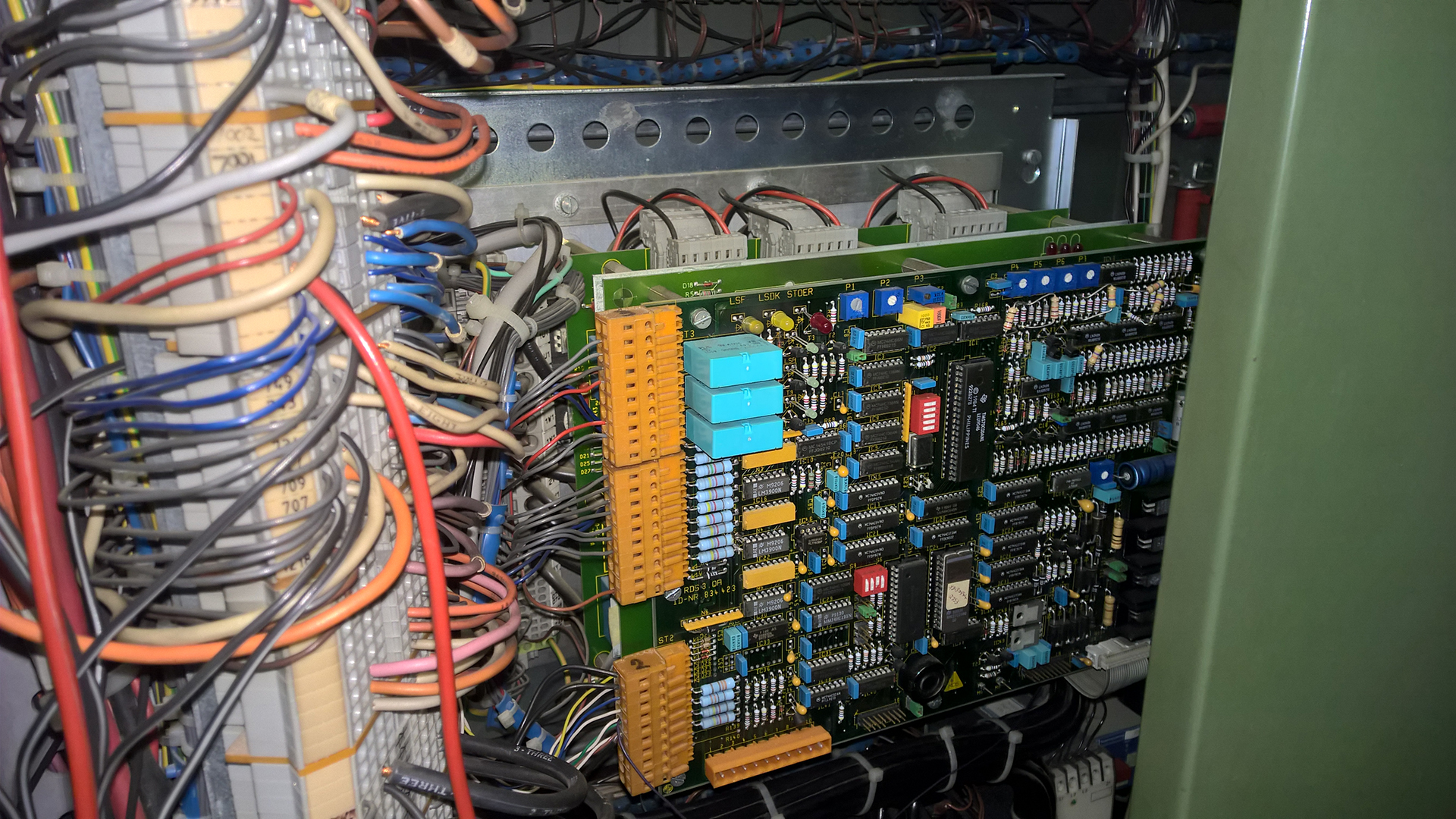

Analogue Control / Modular controls

To reduce upfront cost, and sometimes to save space within a switchboard, contractors may implement standalone time clocks and/or modular input/output (I/O) devices during construction.

While functional, these standalone controls often become an operational burden over time. Integration of legacy systems such as these into a central property or building management system restores full control to the graphical user interface (GUI) and significantly improves overall system management.

Standalone time clocks and modular controls typically require manual checks and adjustments directly at the switchboard. As switchboards can only be accessed by a licensed electrician, even routine changes, such as daylight savings time adjustments or schedule modifications, trigger unnecessary call-outs, delays, and ongoing maintenance costs.

Property system integration removes this friction entirely. Schedules, overrides, and adjustments can be managed centrally, reducing reliance on electrical call-outs and simplifying day-to-day operations. For facility and building managers, this translates into lower operating costs, fewer disruptions, and materially easier asset control over the life of the building.

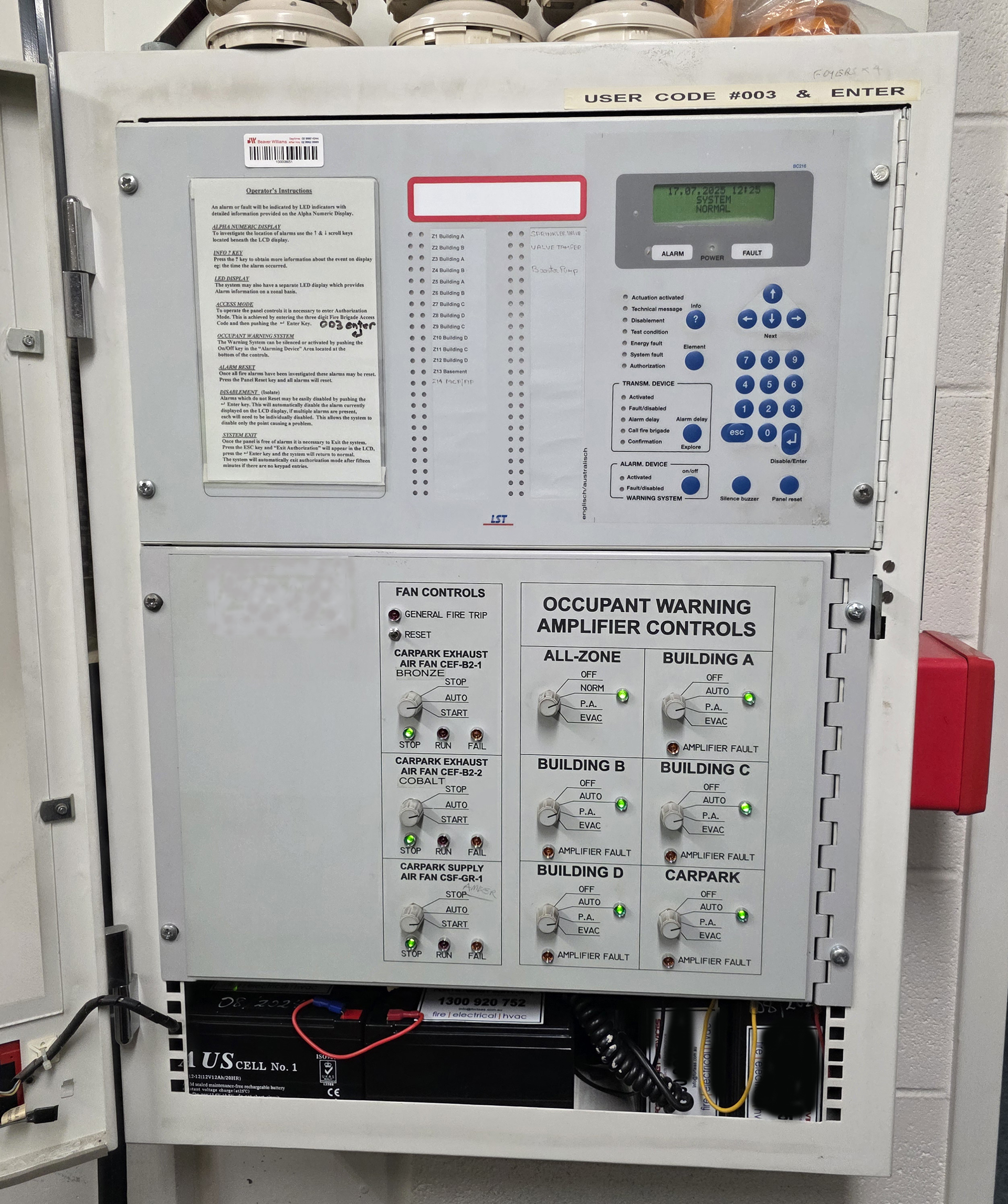

Fire Indication Panels

Legacy Fire Indicator Panels can be integrated efficiently using volt-free contacts and/or sub-relay “daughter” printed circuit boards, enabling reliable low-level interface connections without invasive system upgrades.

The true value of this integration is realised at remote sites, or in buildings where fire contractors attend only once every six months in accordance with AS 1851 inspection intervals.

Remote monitoring provides continuous oversight and peace of mind, delivering immediate notification and response in the event of a fault, alarm activation, power loss, system failure, or other critical fire system conditions—well before the next scheduled inspection.

variable Speed Drives

Most Variable Speed Drives (VSDs)—particularly from major manufacturers—can be readily fitted with interface cards supporting BACnet or LonWorks, in addition to low-level integration via volt-free contacts.

Integrating VSDs into a Building Management System (BMS) enables precise speed control, dynamic load matching, and demand-based operation, all of which are fundamental to energy optimisation strategies in commercial buildings. Rather than operating at fixed speeds or relying on local control only, plant can respond in real time to occupancy, environmental conditions, and system demand—reducing energy consumption and mechanical stress.

From a compliance perspective, centralised monitoring and control supports alignment with energy efficiency obligations, operational performance requirements, and maintenance standards. Faults, run hours, and abnormal operating conditions can be logged and reviewed, improving maintenance planning and providing auditable evidence of responsible plant management.

By integrating existing VSD assets rather than replacing them, building owners achieve measurable energy performance gains, reduced operational risk, and improved compliance visibility, while avoiding unnecessary capital expenditure and extending the service life of critical electrical and mechanical infrastructure.

Elevators and lifts

Older elevator and lift systems are prime candidates for legacy system integration, particularly where full modernisation costs can exceed seven figures. In these scenarios, integration provides a practical alternative—delivering meaningful monitoring and limited control capability without triggering major capital replacement.

By interfacing legacy lift systems with a Building Management System (BMS), commercial property managers gain improved operational visibility and earlier awareness of issues that would otherwise go unnoticed between service visits. Fault monitoring via volt-free contacts enables prompt fault reporting, reducing response times, minimising downtime, and improving tenant experience.

For remotely monitored sites, this approach can generate material cost savings by reducing unnecessary call-outs, reactive inspections, and after-hours attendance. Fault conditions can be verified and prioritised remotely, ensuring contractors are dispatched only when genuinely required and with accurate fault information.

Where supported, integration can also contribute to operational control and energy management, allowing lift operation to be aligned with building usage patterns and after-hours strategies. While integration is not a substitute for full lift modernisation, it represents a cost-effective, risk-managed step that extends asset usefulness, improves oversight, and supports informed capital planning.