Pneumatic Controls Serving Air Conditioning HVAC

Building Management Systems – Pneumatic Controls

Pneumatic Controls: Modern Optimisation for Legacy Systems

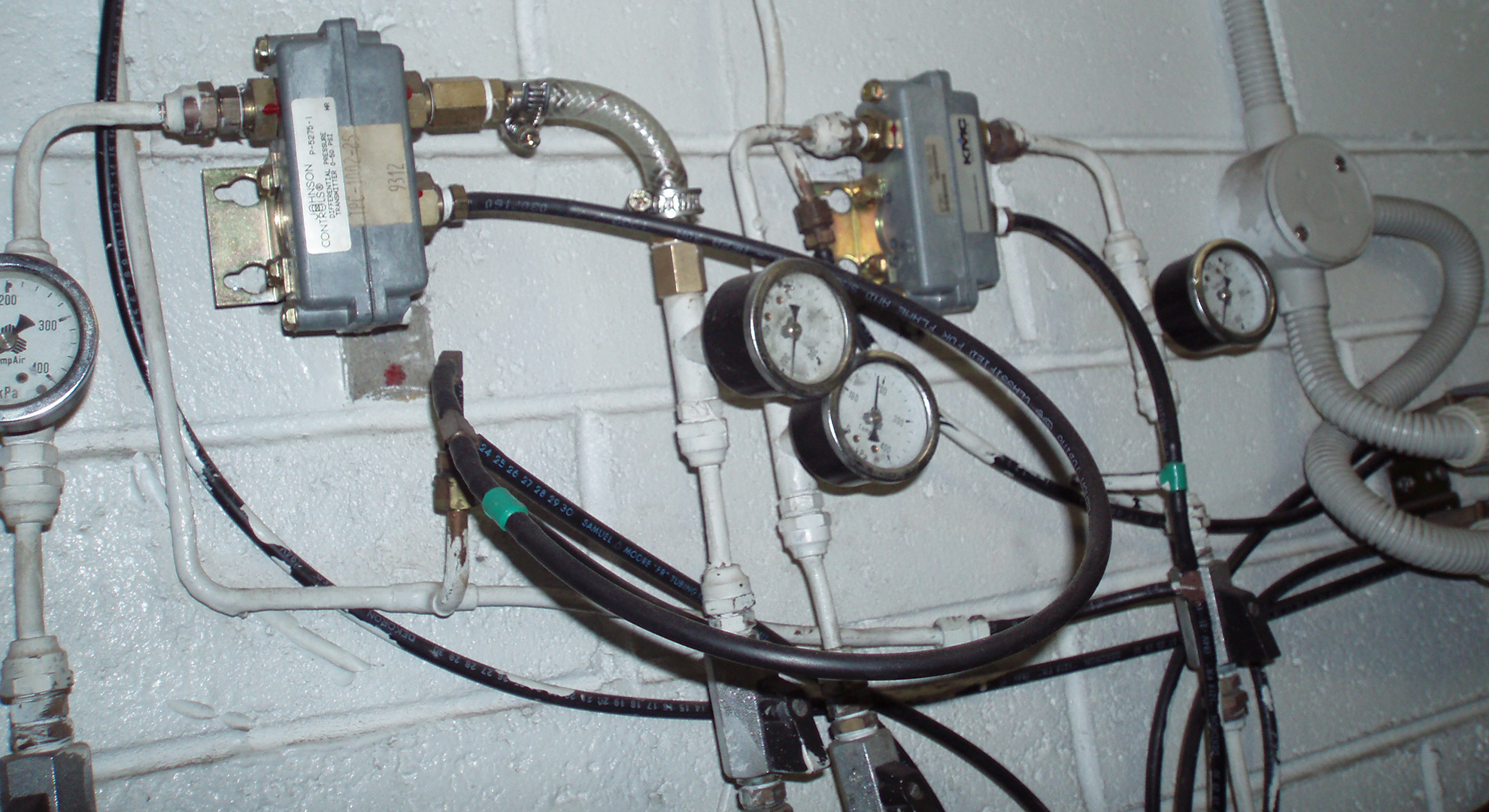

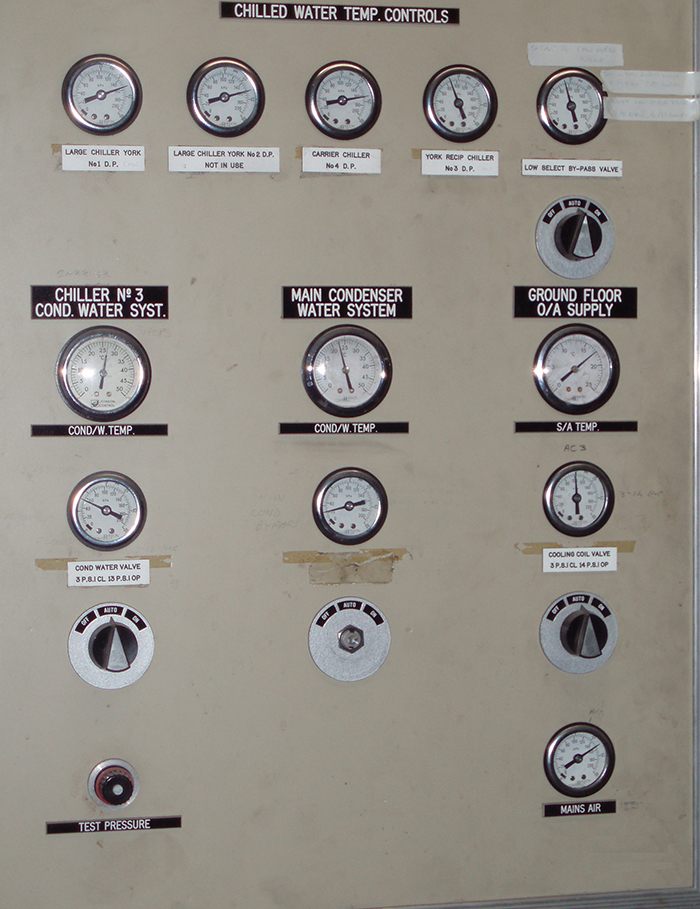

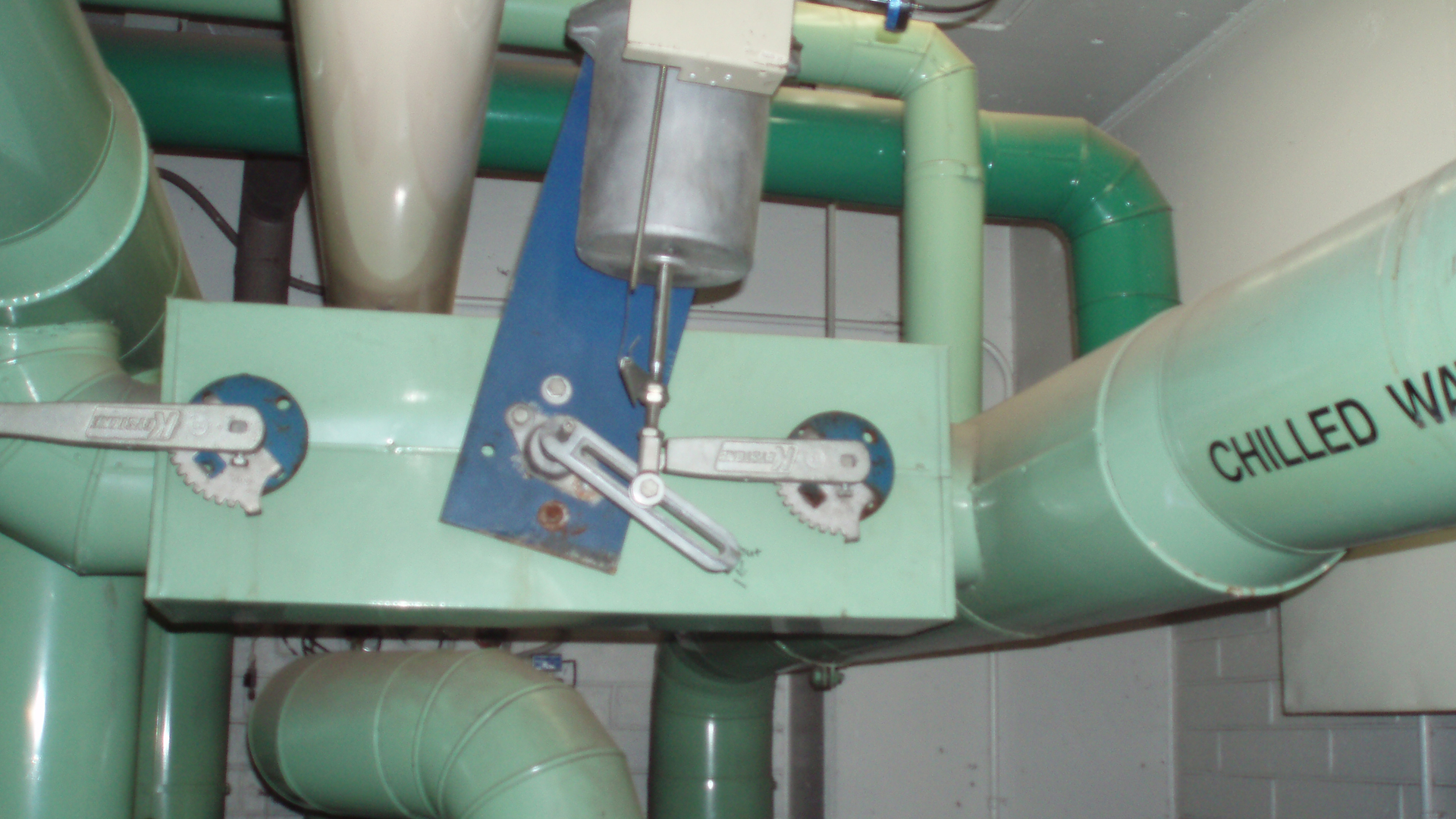

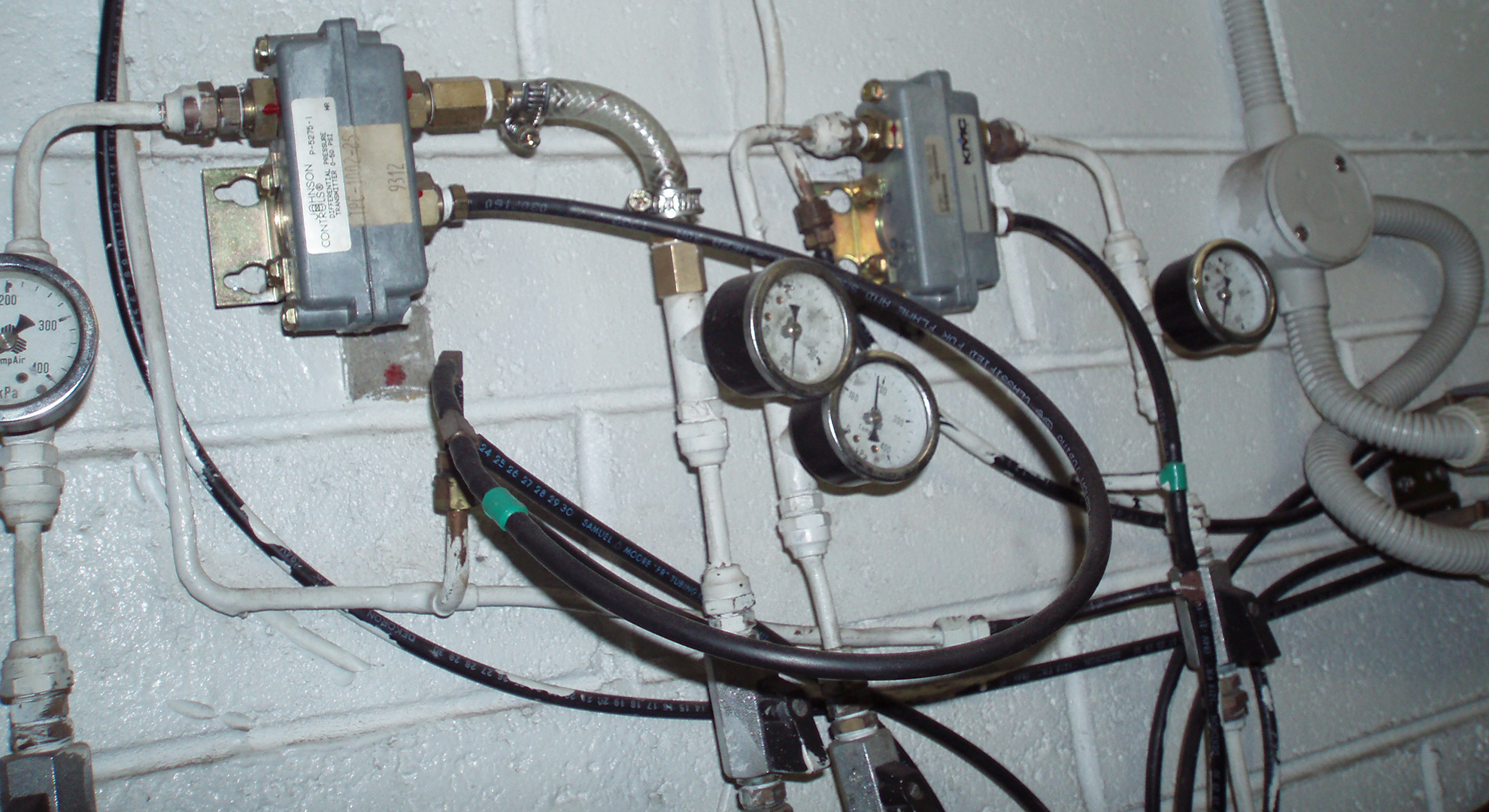

Pneumatic control systems were widely installed throughout the 1970s and 1980s, with major manufacturers such as Honeywell and Johnson Controls supplying thousands of buildings across Australia. While many modern buildings now rely on fully electronic controls, a large number of commercial properties still operate legacy pneumatic systems, particularly for damper and valve actuators. In many cases, these systems remain mechanically sound and reliable—but are no longer operating at their full potential.

Rather than full replacement, a practical and cost-effective solution is to optimise existing pneumatic actuators using modern interface technology.

Air supply quality and control signals is essential to ensure reliability and long-term value.

Optimising Actuator Torque with E-to-P Devices

An E-to-P (Electric to Pneumatic) device allows older pneumatic actuators to integrate seamlessly with modern Building Management Systems (BMS). The device converts a standard 0–10V DC electrical control signal into a proportional pneumatic output—typically in the range of 5 to 25 psi—to drive the actuator.

This conversion enables:

- Improved control accuracy of dampers and valves

- Optimised actuator torque and stroke performance

- Better airflow and water flow regulation

- Reduced hunting, overshoot, and mechanical stress

Why This Matters for Building Owners

Optimising pneumatic actuators delivers tangible benefits without the disruption and capital cost of full system replacement:

- Extended asset life of existing pneumatic equipment

- Improved energy efficiency through more accurate control

- Enhanced comfort for occupants

- Integration with modern controls while retaining proven hardware

For many commercial buildings, this approach provides the best of both worlds—maintaining the robustness of pneumatic systems while gaining the precision and efficiency of modern electronic control.

These systems are often robust and long-lasting, but without proper maintenance and optimisation, they can become inefficient, difficult to control, and costly to operate.

Benefits for Commercial Property Owners

A staged modernisation strategy allows building owners to transition toward fully electronic controls over time, without unnecessary disruption or expense. Pneumatic systems can continue to operate safely and effectively, supported by targeted upgrades that improve performance, compliance, and operational transparency.

By optimising pneumatic actuators rather than replacing them outright, property owners can benefit from:

- Lower capital expenditure compared to full system upgrades

- Improved HVAC control and comfort for tenants

- Better energy efficiency through accurate damper and valve positioning

- Reduced mechanical wear on aging actuators

- Seamless integration with modern BMS platforms

This approach is particularly effective for plant rooms, air handling units, and car park ventilation systems where pneumatic actuators remain structurally sound.

Extending the Life of Existing Pneumatic Systems

In many cases, a full system replacement is not immediately necessary. Existing pneumatic actuators can be retained and integrated into modern control strategies through the use of Electric-to-Pneumatic (E-to-P) transducers.

An E-to-P device converts a standard electrical control signal (such as 0–10V DC) from a modern BMS into a proportional pneumatic output (typically 5–25 psi). This allows precise control of actuator torque and position, improving system responsiveness while maintaining the original pneumatic hardware.

A Practical Upgrade Path

A staged modernisation strategy allows building owners to transition toward fully electronic controls over time, without unnecessary disruption or expense. Pneumatic systems can continue to operate safely and effectively, supported by targeted upgrades that improve performance, compliance, and operational transparency.